EXCELS IN A WORLD UNDER PRESSURE

The all-new Spirolite EF pipe welds easily together to form a stronger, more reliable seal that will not break or leak like other pipe joining systems available today.

As a result, the two joining Spirolite EF joints form a corrosion-resistant, leak-free, durable pipe that can withstand up to 50 PSI!

A leak-free system is not the only advantage our new Spirolite EF offers. When compared to traditionally designed piping systems, it is evident that Spirolite EF outperforms the alternatives in all parameters.

Spirolite Electrofusion vs. Other Pipe Materials |

|||||

|---|---|---|---|---|---|

| Spirolite | Corrugated Metal | Concrete | Fiberglass | Clay | |

|

Lightweight Typical Weight per foot pf 36" pipe (lbs) |

30 | 45 | 565 | 88 | 425 |

| Abrasion Resistant (Darmstadt Procedure 400,000 Cycles) | 0.01" | 0.05" | 0.06" @ 150,000 cycles (max) | 0.05" | 0.03" |

|

Allowed Deflection Before Failure |

20%+ | Less than 2% | ~0 | Long term is 5% or less. | ¼" / FT |

|

Minimum Design Life Span (years) |

100 | 35 | 70-100 | 50 | 50 |

|

Min No. of Joints Per 100 Feet of Pipe |

5 | 2 | 13 | 5 | 10 |

|

Friction/Smoothness (N factor) |

0.009 | 0.022 | 0.013 | 0.010 | 0.014 |

| Withstands PH Level | 1.5 to 14 | 5 to 8 | 4.5 - 6.5 | 7 to 11 (optimally) down to 2 possible | 1 to 14 |

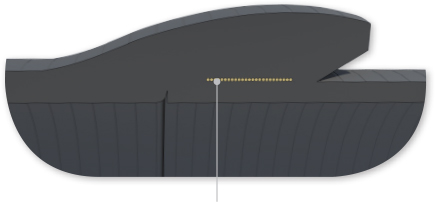

The perfectly electrofused joint forms one continuous pipe and eliminates leaks.

Electrofusion wires are embedded at the manufacturing

stage of the pipe allowing for perfect fusion every time.

Spirolite is cost-efficient, lightweight, durable, weather and corrosion-resistant and can function under a wide temperature range.

SPIROLITE EF CAN WITHSTAND PRESSURE UP TO 50 PSI!

- Cost-efficient HDPE system for municipal and industrial waste applications

- Pressure grade pipe resin

- Leak-free joints

- No corrosion for lifetime of the pipe

- Less maintenance

- Easier to use and faster to install

- Up to 120” ID or larger custom diameter